Zinc metalizing, also known as zinc spraying, is a technique used to apply a zinc coating to steel or iron surfaces. This process provides exceptional corrosion resistance and is widely utilized in industries such as construction, marine, and infrastructure.

The application of zinc coatings protects the underlying metal by acting as a sacrificial anode, which means it corrodes in place of the protected metal.

Contents

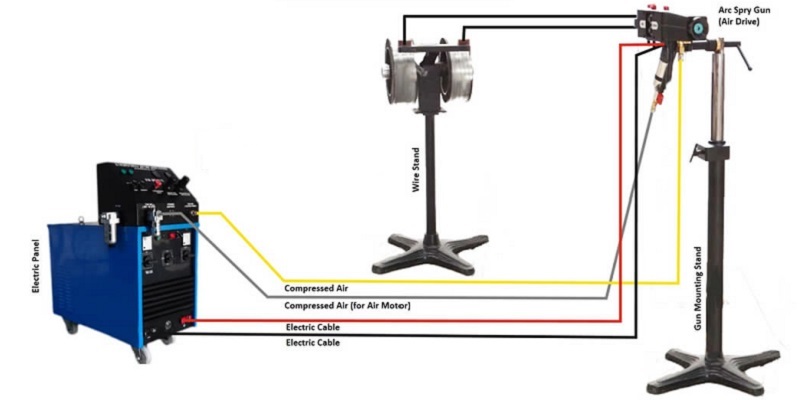

Cost-effective Zinc Metalizing Equipment

Zinc Metalizing Equipment is usually sprayed by utilizing an electric arc spray gun or combustion flame equipment. Arcing the wires causes the zinc covering to melt. The molten metal is then propelled onto the surface by compressed air, which strips pliable Zinc particles from the wire tips. Zinc metalizing is a versatile technique that involves melting Zinc or Zinc Alloy metals and rapidly propelling the molten Zinc particles onto a prepared substrate, resulting in a lamellar or layered coating. Metalizing coating, also known as thermal spraying, is a highly effective and well-proven method of corrosion prevention that provides galvanic and barrier coating protection to iron and steel.

Zinc metalizing equipment, a combination of film coating strategies in which finely disseminated metallic or nonmetallic components are gathered in a liquid or semi-liquid state to frame a coating. The Zinc metalizing equipment film coating component might be as powder, ceramic pole, wire, or liquid materials.

Importance of Zinc Metalizing Equipment

The quality and efficiency of zinc metalizing are heavily dependent on the equipment used. Advanced zinc metalizing equipment ensures a consistent, durable, and high-quality zinc coating, which is essential for extending the lifespan of metal structures. Here, we explore the various types of zinc metalizing equipment, rules, their features, and benefits.

Rule of Zinc Metalizing Equipment

Metalizing gun process is predicated on an identical technique for warming and dissolving a feedstock material, ordinarily inside the kind of powder or wire prior to speeding up it to a high speed then, at that point, permitting the particles to strike the substrate surface.

The fundamental component of all Zinc metalizing equipment coatings is their lamellar grain structure coming about because of the quick cementing of little globule particles, smoothed from striking a cold surface at high speeds.

The coating is made when numerous particles are saved on top of each other. These pieces are mechanical or metallurgical connected to the substrate.

There are different kinds of Zinc metalizing equipments accessible by which diverse coating of specific materials can be covered on the substrate.

Benefits of Zinc metalizing Spray coatings

Diminished Cost: The expense of fixing the part is a more modest sum than purchasing a substitution one. Regularly, the coating really keeps going longer than the primary material utilized.

Low Heat Input: Among certain exclusions, the metalizing spray process drops the part’s warm past alone.

Flexibility: Practically any metal, fired, or plastic is regularly thermally sprayed.

Thickness Range: Contingent upon the texture and shower framework, coatings are frequently sprayed from 0.001 to very 1 inch thick. The thickness normally goes from 0.005-0.1 inches.

Handling Speed: The spray rates range from 3-60 lb/hr relying on the texture and accordingly the shower framework. Average rates for material application are 1/2 – 2 lb of texture for every square foot per 0.01-inch thickness.

Types of Zinc metalizing Coating

- Wire Flame Spray coating

- Electric Arc Wire Spray Gun coating

WIRE FLAME SPRAY COATING

Wire Flame Spray gun coating is a metalizing procedure that utilizes an oxygen-fuel gas fire as a hotness hotspot for liquefying the wire (coating material). Here, Compressed air is employed for atomizing and propelling the material to the workpiece. The strategy for fire showering utilizing wire is known as metalizing or wire fire splashing.

ELECTRIC ARC WIRE SPRAY COATING

In the electric Arc Spray Coating strategy, 2 wires of the material turned on the power at the spout of the showering gun square measure condensed with a shortcircuited curve, then, at that point, the melted materials square measure fine-grained and splashed onto the topics with packed gas. Electric Arc Spray Coating and wire flame spray gun measure together known as wire processes. All metals and combinations in wire kind square measure out there for bend showering material.

Zinc Metalizing Equipment in India

Shot Blasting Machine is the leading Manufacturer of Zinc Metalizing Equipment, Electric arc spray gun, flame spray gun, zinc thermal spray equipment, thermal spray gun in India at low price for sale. We are also provide sand blasting machine, shot blasting machine, sand blasting cabinet, shot peening machine, paint booth system, dust collector, thermal spray wire, abrasive media.