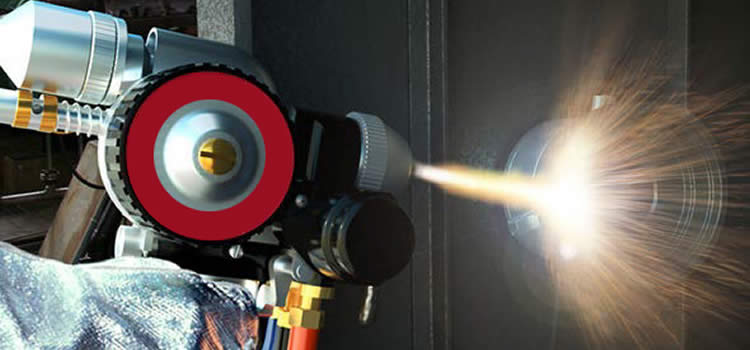

A Flame Spray Gun is a warm spraying strategy that uses an oxygen-fuel gas streak as a hotness supply for softening the wire (covering material). Here, Compressed air is used for atomizing and pushing the material to the workpiece. The motivation behind flame spraying using wire is known as wire flame spraying.

Contents

Flame Spray Gun Process:

The material is embedded in a gun and nozzle and gets dissolved in the oxygen fuel gas flame. An air stream from the gun drives the atomized particles to the workpiece. At the point when the wire is used for a surfacing substance, it is filled into the nozzle by an air-driven wire feeder and gets softened in the gas flame. The flame spray gun approach has the advantage of being able to apply coatings nearly instantly, with no drying period and little chance of harming the element.

If necessary, flame spray gun systems can be operated manually, semi-automatically, or entirely automatically. Copper wire, zinc wire, aluminium wire, brass, nickel, steel, stainless steel, and other metals are commonly used. In the thermal spray coating, metals and metal alloys in the form of wire are employed for spraying.

Wire Flame Spray Coating Gun (12M and 13M)

Working of the Wire Flame Spray gun 12M is straightforward and starts by pushing the metalizing wire in the gun, consuming the fuel gas, and enacting the fast activity wire hold to take care of the wire into the Flame. It ends by basically pushing the wire grasp control. The exceptional siphon fitting and general gas head configuration permit the 12M to deliver high splash rates with insignificant gas utilization. The plan is additionally exceptionally impervious to the 12M gun is provided with standard drive rolls and cogwheels, which are reasonable for use with “hard” wires.

The 12M-Hand 12M-HT guns, Paint stripping machine produced by us is of very fine quality. designed to shower delicate wires, come furnished with an extraordinary non-load air cap just as a rapid turbine shaft and countershaft gears. All 12M and 12M-H guns are display lines positioned for acetylene as the fuel gas, while the gun is developed for use with propane and the the12M-HT for propylene and propane fuel gases. In any case, by considering discretionary equipment, the widespread gas head configuration can be adjusted to utilize other fuel gases, like acetylene, hydrogen, propane, gaseous petrol, MAPP, or MPS. Tungsten carbide has a very prolific property.

Power Flame Spray Gun

The coating process is carried out using a powder flame spray gun, and the coating material is in powder form, making the method simple. The powder flame spray gun uses a similar technology to the Flame Spray Gun, except instead of wire, a powder is used as the feedstock.

Activity Manual of Flame Spray Gun

Wire Feed – Air Turbine

Wire Size Standard-1/8″ (3.17mm)

Wire Size Optional-15G, 11G, 5/32″, 3/16″ (4.76mm)

Gasses Used-Oxygen and Fuel Gas

Fuel Used-Acetylene or LPG/Propane and so on

Compacted Air-35 CFM at a tension of 5 bar or 75 psi

Net Weight-Approx 2.7 Kg. (Gun Only)

Highlights Of Flame Spray Gun:

• Appropriate for Engineering wires, prepares, copper, and bronzes + against consumption materials.

• Huge regions are splashed proficiently

• divider control board with Safety shut-off valve

• Use fuel like Oxygen, Nitrogen as it were

• Conductive coat applications.

• best for Portable for an on-location coat.

• Gives protection from wear, scraped area, and disintegration.

• Warm obstruction coat to secure constructions and materials

• Gives Corrosion obstruction in air and marine conditions

• It gives security against high-temperature oxidation, disintegration, and erosion

• Electrical obstruction, electrical conductivity, or electromagnetic protecting

• Building composite creations of metals and earthenware production

Applications Of Flame Spray Gun:

• For wear coatings, molybdenum

• Non-ferrous metals covering, copper, bronze covering

• Fine covering with low hotness input

• For recovering the pieces of roller and shafts

Successful

• Flexible equipment choices that license the gun to be arranged for use with hard and delicate wires in a sort of distance across.

• Wire drive takes care of wire dependably, reliably, and uniform movement, regardless of vacillations in pneumatic stress.

• It is planned toughly and worked for delayed assistance existence with low support

• Gas head gadget holder permits simple and quick set up of shower gas tensions and moves before gun burning.

• It is a basic activity that requires the least administrator preparation.

• The fixing of O-ring among nozzle and siphon plug ensures freedom from any dangerous activity and explains gun upkeep.

• Upkeep and equipment change over the nozzle is extremely basic, Robotic grit blasting machine produced by us is of prolific quality. siphon fitting and driving wire guide gadgets can be effortlessly disposed of and supplanted by a total unit.

Flame Spray Gun Price

Shot Blasting Machine is the leading Manufacturer of Flame Spray Gun in India at a low price for sale. we are also Manufacturer of Wire Flame Spray gun, powder flame spray gun, thermal spray gun, metalizing gun, zinc spray gun, arc spray gun, portable Sand Blasting Machine, shot blasting machine, grit blasting machine, Sand Blasting Cabinet, Sand Blasting Nozzles, Shot blasting room, in India for sale.