Tungsten carbide powder (WC) highlights a novel mix of properties like amazingly high hardness joined with extremely high modulus of flexibility, just as high electrical and warm conductivity. With around 60% tungsten carbide is the most habitually utilized tungsten compound and is normally utilized in hard metals based on WC-Co, WC-blended carbide-Co, WC-Co/Ni/Fe, or in cermets. The nature of the Tungsten Carbide Powders is basic for the combined properties.

Cutting tools and high wear surfaces are two of the most common applications for tungsten carbide. Our stringent quality assurance approach ensures that our powders meet the highest standards of consistency and quality. We are constantly able to draw on our 25 years of experience to design specialized materials that will improve the results of your specific applications and assembly procedures. Tungsten carbide powder is also the basis for our thermal spray powders, which provide hard, wear-resistant surface coatings. To answer your problems, we provide a wide range of molecular sizes and densities.

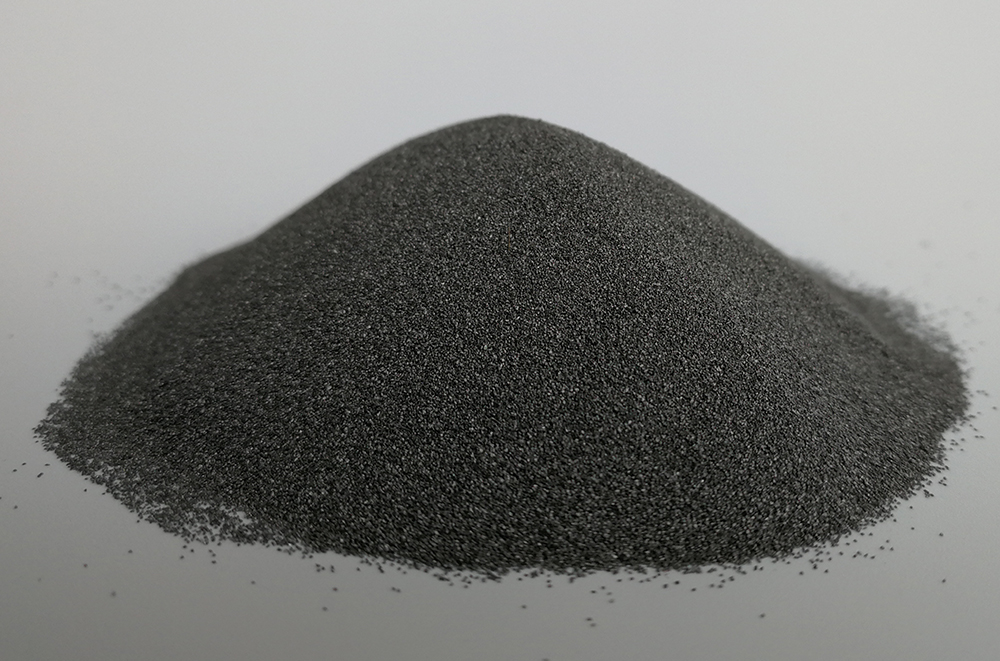

Tungsten carbide (chemical equation: WC) is a chemical compound (explicitly, a carbide) containing equivalent pieces of tungsten and carbon molecules. In its most essential structure, it is a fine dim powder, however, it tends to be squeezed and framed into shapes through a cycle called sintering for use in modern hardware, cutting instruments, abrasives, protection penetrating shells, and gems.

This powder is around twice as solid as steel, with Young’s modulus of roughly 530–700 GPa, and is twofold the thickness of steel—almost halfway between that of lead and gold. It is equivalent with corundum in hardness and can be cleaned and completed distinctly with abrasives of predominant hardness like cubic boron nitride and precious stone powder, haggles.

Contents

Specifications of Tungsten Carbide Powder

| POWDER NAME & COMPOSITION | CHEMISTRY & SIZE | CHARACTERISTICS | SAFETY DATA SHEET (SDS) |

| WC-104WC-12Co(Cast) | Co 12.0C 3.9W balance-125 µm/+45 µm | · Excellent low-temperature wear properties· Dense, hard coating with marginal oxidation and corrosion resistance· Useful up to 900°F / 482°C | WC-104 |

| WC-106WC-12Co(Cast) | Co 12.0C 3.9W balance-45 µm/+5 µm | · Excellent low-temperature wear properties· Dense, hard coating with marginal oxidation and corrosion resistance· Useful up to 900°F / 482°C | WC-106 |

| WC-819WC-10Co(Agglomerated & Sintered) | Co 10.0Cr 5.3C 4.0W balance-45 µm/+16 µm | · Lower-cost alternative to 1350VM· Densified structure with fine carbide dispersion promotes finer microstructure, better DE and denser, smoother coatings· Useful up to 900°F/482°C | WC-819 |

| WC-114WC-12Co(Sintered & Crushed) | Co 12.0C 5.4W balance-45 µm | · Excellent low-temperature wear properties· Dense, hard coating with marginal oxidation and corrosion resistance· Useful up to 900°F / 482°C | WC-114 |

| WC-489-1WC-12Co(Sintered & Crushed) | Co 12.0C 5.4W balance-45 µm/+16 µm | · Excellent low-temperature wear properties· Dense, hard coating with marginal oxidation and corrosion resistance· Useful up to 900°F / 482°C | WC-489-1 |

| WC-726 / 1320QWC-11Co(Agglomerated & Sintered) | Co 11.0C 4.0W balance-45 µm/+5 µm | · Excellent low-temperature wear properties· Dense, hard coating with marginal oxidation and corrosion resistance· Useful up to 900°F / 482°C | WC-726 / |

| WC-793WC-11Co(Agglomerated & Sintered) | Co 11.0C 4.0W balance-45 µm/+16 µm | · Excellent low-temperature wear properties· Dense, hard coating with marginal oxidation and corrosion resistance· Useful up to 900°F / 482°C | WC-793 |

| WC-727 / 1342VFWC-12Co(Agglomerated & Sintered) | Co 12.0C 5.5W balance-38 µm/+11 µm | · Similar properties as other WC-12Co· Densified structure with fine carbide dispersion promotes finer microstructure, better DE and denser, smoother coatings· Excellent flowability· Useful up to 900° F / 482° C | WC-727 / 1342VF |

| WC-727-1 / 1342VMWC-12Co(Agglomerated & Sintered) | Co 12.0C 5.5W balance-45 µm/+16 µm | · Similar properties as other WC-12Co· Densified structure with fine carbide dispersion promotes finer microstructure, better DE and denser, smoother coatings· Excellent flowability | WC-727-1 / 1342VM |

| WC-727-5WC-12Co(Agglomerated & Sintered) | Co 12.0C 5.5W balance-31 µm/+11 µm | · Similar properties as other WC-12Co· Densified structure with fine carbide dispersion promotes finer microstructure, better DE and denser, smoother coatings· Excellent flowability· Useful up to 900°F / 482°C | WC-727 / 1342 |

| WC-727-6WC-12Co(Agglomerated & Sintered) | Co 12.0C 5.4W Rem-38 µm/+5 µm | · Similar properties as other WC-12Co· Densified structure with fine carbide dispersion promotes finer microstructure, better DE and denser, smoother coatings· Excellent flowability· Useful up to 900° F / 482° C | WC-727-6 |

| WC-729 / 1343VFWC-17Co(Agglomerated & Sintered) | Co 17.0C 5.0W balance-38 µm/+11 µm | · Higher Co levels for better toughness, impact strength and ductility· Densified structure promotes superior coating density and powder flow· Useful up to 900° F / 482° C | WC-729 / 1343VF |

| WC-729-1/1343VMWC-17Co(Agglomerated & Sintered) | Co 17.0C 5.0W balance-45 µm/+16 µm | · Higher Co levels for better toughness, impact strength and ductility· Densified structure promotes superior coating density and powder flow· Useful up to 900° F / 482° C | WC-729-1 / 1343VM |

| WC-729-5WC-17Co(Agglomerated & Sintered) | Co 17.0C 5.0W balance-31 µm/+5 µm | · Higher Co levels for better toughness, impact strength and ductility· Densified structure promotes superior coating density and powder flow· Useful up to 900° F / 482° C | WC-729-5 |

| WC-128-2WC-17Co(Sintered & Crushed) | Co 16.8C 5.2W balance-53 µm/+22 µm | · Higher Co levels provide better toughness, impact strength and ductility than WC-12Co· Densified structure promotes superior coating density and powder flow· Useful up to 900°F / 482°C | WC-128-2 |

| WC-559WC-17Co(Plasma Densified) | Co 16.8C 5.2W balance-53 µm/+22 µm | · Higher Co levels for better toughness, impact strength and ductility· Densified structure promotes superior coating density and powder flow· Useful up to 900°F / 482°C | WC-559 |

| WC-724 / 1310VFWC-10Ni(Agglomerated & Sintered) | Ni 10.0C 5.5W balance-45 µm/+11 µm | · Better corrosion protection than WC-Co· Excellent low-temperature wear properties up to 900°F / 482°C· Superior deposition efficiency (DE) | WC-724 / 1310VF |

| WC-724-1/1310VMWC-10Ni(Agglomerated & Sintered) | Ni 10.0C 5.5W balance-53 µm/+16 µm | · Better corrosion protection than WC-Co· Excellent low-temperature wear properties up to 900°F / 482°C· Superior deposition efficiency (DE) | WC-724-1 / 1310VM |

| WC-113WC-Co-Cr(Sintered) | Co 10.0Cr 4.0C 5.3W balance-45 µm/+5 µm | · Improved oxidation and corrosion protection over WC-Co and WC-Ni· Excellent low-temperature wear properties· Useful up to 900°F / 482°C | WC-113 |

| WC-436-1WC-Co-Cr(Sintered) | Co 10.0Cr 4.0C 5.3W balance-53 µm/+16 µm | · Improved oxidation and corrosion protection over WC-Co and WC-Ni· Excellent low-temperature wear properties· Useful up to 900°F / 482°C | WC-436-1 |

| WC-731 / 1350VFWC-Co-Cr(Agglomerated & Sintered) | Co 10.0Cr 4.0C 5.3W balance-38 µm/+11 µm | · Similar properties as other WC-Co-Cr· Densified structure with fine carbide dispersion promotes finer microstructure, better DE and denser, smoother coatings· Excellent flowability· Useful up to 900°F / 482°C | WC-731 / 1350VF |

| WC-731-1 / 1350VMWC-Co-Cr(Agglomerated & Sintered) | Co 10.0Cr 4.0C 5.3W balance-45 µm/+16 µm | · Similar properties as other WC-Co-Cr· Densified structure with fine carbide dispersion promotes finer microstructure, better DE and denser, smoother coatings· Excellent flowability· Useful up to 900°F / 482°C | WC-731-1 / 1350VM |

| WC-731-6WC-Co-Cr(Agglomerated & Sintered) | Co 10.0Cr 4.0C 5.3W Rem-31 µm/+5.5 µm | · Similar properties as other WC-Co-Cr· Densified structure with fine carbide dispersion promotes finer microstructure, better DE and denser, smoother coatings· Excellent flowability· Useful up to 900°F / 482°C | WC-731-6 |

| WC-496WC-CrC-Ni(Sintered & Crushed) | Cr 20.0Ni 6.3C 5.9W balance-45 µm/+16 µm | · Superior oxidation and corrosion properties than other WC-based materials· Better chemical resistance than other WC-based materials· Useful up to 1400°F / 760°C | WC-496 |

| WC-733 / 1356VMWC-CrC-Ni(Agglomerated & Sintered) | Cr 20.0Ni 6.5C 5.8W balance-45 µm/+16 µm | · Similar properties as other WC- NiCr· Densified structure with fine carbide dispersion promotes finer microstructure, better DE and denser, smoother coatings· Excellent flowability· Useful up to 1400°F / 760°C | WC-733 / 1356VM |

| WC-735-1WC-12Co+50Ni(Blended) | Ni 36.3Cr 7.3Fe 2.3Si 2.3B 1.6WC-12Co balance-53 µm/+16 µm | · Excellent combination of abrasion resistance and toughness· Economical solution to severe wear applications· Useful up to 900°F / 482°C | WC-735-1 |

Tungsten Carbide Powder Manufacturer in India

Sintered tungsten carbide–cobalt cutting instruments are very scraped spot safe and can likewise withstand higher temperatures than standard high-velocity steel (HSS) apparatuses. Carbide cutting surfaces are frequently utilized for machining through materials like carbon steel or treated steel, and in applications where steel instruments would wear rapidly, like high-amount and high-accuracy creation. Since carbide instruments keep a sharp bleeding-edge better compared to steel apparatuses, they are by far large and produce a superior completion on parts, and their temperature obstruction permits quicker machining.

Tungsten Carbide Powder Applications

Tungsten carbide powder is used in sand blasting and metalizing fields. In sand blasting machine the most important component is the nozzle by which blasting is done on the material and is made up of tungsten carbide powder, due to its wear resistive property. The nozzles come in different shapes and sizes of tungsten carbide. i.e 6mm, 8mm, 10mm,12mm, Straight nozzle, angular nozzle, etc.

- Manufacturers of diamond tools use it as additives to improve cutting.

- It is also used to manufacture heavy alloy products like tank piercing rod, balls, counter balance and as a weight filler.

- Alloys such as Copper/Silver tungsten are used in electrical contacts, electrodes and heat sinks.

- Tungsten powder is used to manufacture radiation shielding and induction accelerators in nuclear fields.

- New applications are found in the form of Tungsten plastic and Tungsten putty for fishing sinker and racing car weight

Tungsten Carbide Powder Price

Tungsten Carbide powder price depends on several factors like its composition etc. These are shown in detail below. In Metalizing Industry, tungsten carbide powder is used as a coating material used in HVOF Coatings for wear and tear resistance.

| Avg. particle size range | Density |

| 1 – 2 micron | 2.8 g/cc |

| 2 – 3 micron | 3.2 g/cc |

| 3 – 4 micron | 3.8 g/cc |

| 5 – 6 micron | 4.2 g/cc |

| 8 – 10 micron | 5.0 g/cc |

| 13 – 15 micron | 6.2 g/cc |

| 75 – 150 micron | 10.0 g/cc |

Tungsten Carbide Powder for Sale

We offer tungsten carbide powder for sale in India at a low price. We also provide steel shot, SS shot, copper slag, steel grit, garnet sand, quartz shot, aluminum oxide, glass beads, etc. We provide a large range of products and are checked on various parameters, such as density, physical and chemical properties, microstructure, hardness, durability. We are focused on our quality products and customer satisfaction.