Robotic Grit Blasting Machine is a surface treatment strategy by and large used in a wide range of ventures for quite some time purposes. Abrasive Robotic Grit Blasting Machine is the strategy by which an abrasive media is invigorated through a Grit blasting spout through packed air.

Robotic Grit Blasting Machine is the interaction where little precise or circular particles are moved at a section by packed air, or mechanical fast pivoting wheels or water siphons. The impact media type, shape, size, thickness, and hardness, alongside media speed increase and volume of media, joined with blasting separation from the work piece, point of effect, and time cycles are significant variables in the impact interaction abilities. The robotic grit blasting machine is created to convey, recover and contain the media, contain the part to be impacted, and gather the residue from the blasting system. Parts can be handled separately as a bunch processor can be mechanized through the framework.

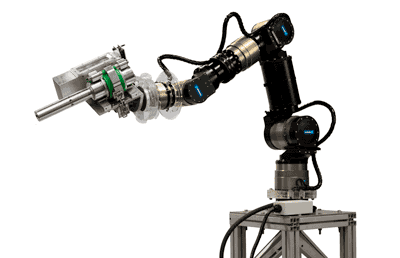

A blast cannon manipulator is coupled to a 52 x 32-inch rotary grit blasting cabinet, which is controlled by a servomotor-driven 24-inch turntable as a seventh axis of coordinated robotic motion. During the programmed process routine, a part-holding fixture securely coupled to the table positively locates the component, which can be orientated or rotated at a controlled speed.

The spindle or turntable is built with core air provided to allow a positive and adjustable flow of purge air into the component during blasting for grit-blast preparation of components with through-holes, vents, or internal passageways where material could collect during processing. If tight table run-out tolerances are required, the blast system manufacturer can use custom robot end-of-arm tooling to accomplish the machining in place.

The robotic grit blasting machine system’s ability to maintain the appropriate blasting angle, nozzle-to-surface distance, and surface speed while precisely following the curves of complex-shaped parts is critical to eliminating over-blasted and under-blasted component surfaces. The robotic blasting machine, which uses a single blast cannon, repeats the motion program every time, and the system can store and remember process recipes for over a hundred distinct components. Because the operator just needs to install the interchangeable fixture and identify the relevant program to prepare for grit-blasting a new component, significant productivity benefits can be gained by eliminating the need for set-up for various parts.

Precision roughening necessitates improved blast media supply and reclamation in addition to the precise and repeatable grit blasting nozzle and component motion. This ensures that the miniature grit projectiles that actually conduct the task of surface modification are thoroughly controlled. To improve the uniformity of the surface finishing results, features such as automatic blast pressure regulation, media flow detection, media level sensing, automatic media replenishment, and screen classification of the blasting grit are provided.

Robotic Grit Blasting Machine applications :

- roughening surfaces in anticipation of warm splashing, painting, holding, or other covering tasks

- eliminating rust, scale, sand, or paint

- eliminating burrs

- giving a matte surface completion

- eliminating streak from formed parts

- corrective surface upgrade or scratching

As of late, society has seen an ascent in the utilization of robotics that has upset incalculable enterprises. With regards to abrasive blasting for surface readiness and getting done, inventive new advances are depended on progressively in the assembling system.

Robotic Grit blasting Machine is a state of the art strategy for cleaning, stripping, planning, or potentially completing metal surfaces securely, definitively, and proficiently. A computerized blasting framework eliminates the administrator from the blasting climate, keeping them out of danger while considering persistent activity to amplify uptime and usefulness. The remote-controlled framework accommodates the change of the speed and way of the spout, while a residue gatherer and media reclaimer catch airborne particles and make it conceivable to reuse impacted abrasive media.

Benefits of an Robotic Grit Blasting Machine

From working on quality outcomes and unequaled dependability to upgraded well being and adaptability, there are many motivations to pick robotic abrasive blasting. To comprehend the reason why this advanced strategy is turning out to be so famous in assembling, auto, modern canvas and covering, and numerous different businesses, think about a portion of the advantages of computerized blasting:

Worked on quality: Using a robotic framework takes into account predictable surface quality gathering the severe determinations of every extraordinary venture. You can kill mistakes because of human oversight and guarantee you’re blasting at the appropriate point to yield the ideal outcomes.

Expanded efficiency: The capacity to run persistently with decreased work prerequisites helps increment adaptability and increase usefulness. Robotic abrasive blasting frameworks can support your ability dramatically and accelerate processes while further developing accuracy. You can profit from a quicker ideal opportunity to advertise and a superior main concern.

Remarkable solidness: Robotic blasting Machine hardware is equipped for facing the hardest positions and the most forceful blasting conditions. Units are intended to keep out residue and dampness and withstand impacts for expanded help life.

Higher proficiency: Innovative abrasive blasting frameworks increment item yield and stream while bringing costs related down to support, utilities, and material misfortune. The minimized size diminishes space prerequisites, while accuracy robotics takes out botches, re-work, and returns.

More secure places of work: With mechanized robotic blasting, you don’t need to stress over laborers getting harmed or presented to unsafe pollutants, so there’s no extra well being clothing or frill expected to shield your staff from dangerous openings.

Robotic Grit blasting Machine in India

Shot Blasting Machine is the leading manufacturer of Robotic Grit blasting Machine in India at a low price for sale. We are also offering sand blasting machine, grit blasting machine, shot blasting machine, portable sand blasting machine, sand blasting cabinet, grit blasting machine, thermal spray gun, abrasive media in India as the customer requirement.