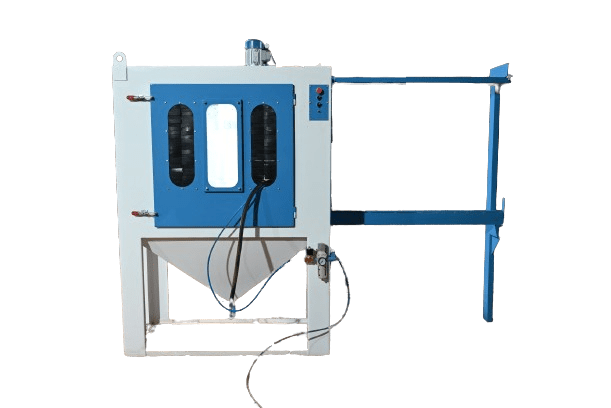

Granite engraving machine is painting engraving for granite, natural stone, glass, ceramic of high-tech entirely automatic engraving equipment. Granite engraving type machine by stone conveying system, computer control system, engraving system & equipment frame composed. The granite stone engraving machine design gets caught in the surface when it operates with garnet sand, a sand blasting gun, an air compressor, and other tools like a vacuum pump, reclaimer, storage tank, dust collector (reverse pulse jet pleated filter), powder-coated tungsten carbide nozzle, and additional granite engraving machine fragments.

The granite stone engraving machine is instantly the most excellent actually high-tech totally automatic engraving machine on the granite, natural stone material, ceramic tile, and glass in India. The machine overwhelms the additional standard engraving machine carved stone when efficiency is not heightened, the disadvantages of systematic failure, its comfortable durable, rich software, and professional quality.

Contents

Granite Engraving Machine Specifications

| Product | Granite Engraving Machine |

| Type of Nozzle | Tungsten / Boron Carbide Nozzle |

| Nozzle Diameter (mm) | 6 – 10 mm |

| Compressed air requirement (CFM) | 25 – 90 CFM |

| Blasting hose | 6 – 8 Mtr. |

| Material | Mild Steel |

| Storage Capacity | 28 Lit. |

There is no previous expertise necessary to immortalize your company brand or favorite photo in stone with our granite engraving equipment; all you ought is a definitive power association to get started. When engraving on granite, you are not instructed to wear protective eyewear or follow other safety precautions. Operating with a sand blasting machine is absolutely safe.

Our granite engraving type machine allows you to effortlessly produce picture engravings & grave stone engravings, additionally engrave a corporate logo on granite.

Granite engraving machine is straightforward to use, so you may acquire amazing outcomes unaccompanied by previous experience. All you demand is a granite stone engraving machine, blast media, a typical power supply, & sand blast foil with your preference motif.

The unique vacuum blasting machine technology, furthermore comprehended as the negative pressure jet procedure, allows any selected picture pattern to be discharged onto the granite slabs.

Granite Engraving Machine Working

You simply require to push the sand blast foil onto a clean exterior of granite and apply a little moisture before you could begin engraving granite utilizing the granite marble engraving machine. The jet hood ought to put on the foil & blasted accompanied by a jet lance until the appropriate deep is accomplished in all regions. The etching may be viewed via vision panels on the jet hood.

When the granite engraving is exhausted, the sand blast foil must be released, & the job is concluded. To accentuate the difference, employ white color afterward.

Types of Granite Engraving Machine

Manual Granite Engraving Machine

Granite is manually engraved utilizing a manual granite engraving machine. Skilled engravers are essential for this job. It provides a much clearer & more even texture finish. An authority of air is needed for this style of machine so that air can pass via a pipe on the headpiece & an engraving mechanism be functionally dragged release.

While automatic engraving machines which generally do not require any effort for the engraving process have largely replaced manual engraving machines, there are still a number of situations in whichever a manual engraving machine is unsuitable.

Automatic Granite Engraving Machine

An automatic granite engraving machine could operate externally & need a significant amount of manual labor. It allows elimination grinds intended to end a massive amount of metal. It suggests deference to accuracy & alliteration, whichever is appropriate for most metals. It is recognized for its persistent & creative engraving. For the workshop, commerce, & industrial purposes, automatic engraving machines are monitored. They provide far better engraving on consistency & provide more appropriate deep-draw scrapes into metal. In addition to the benefit of trembling elderly hardware, intramural strain & dust may be effectively reneged for a prolonged period of time externally shoving to some degree of capacity deformity.

An automated engraving machine is even typed in 2 routes. for instance;

- CNC Granite Engraving Machine

- Roller Conveyor Shot Blasting Machine

Granite Engraving Machine Application

- Monument Engraving: Gravestones, memorials, & monuments are frequently made with granite engraving equipment. They improve the finished product’s visual appeal by enabling complex designs & accurate typography.

- Architectural Engraving: Granite stone engraving machines are utilized in the construction sector for architectural purposes, including engraving on building facades, walls, & floors. For both commercial & residential developments, they make personalization and branding options possible.

- Artistic Engraving: Granite marble engraving machines are used by artists and craftspeople to create one-of-a-kind sculptures, artworks, & ornamental items. This equipment allows for both artistic flexibility and precise translation of complex motifs onto granite exteriors.

Granite Engraving Machine Price

We are the foremost manufacturer and supplier of granite engraving machines in India. Our granite engraving machine price is low compared to others. We also offer abrasive blasting machines, shot blasting machine, sand blasting machines, portable shot blasting machine, shot peening machines, dry ice basting machine, paint stripping machines, paint booth systems, thermal spray guns, thermal spray wires, dust collectors, abrasive media, etc.