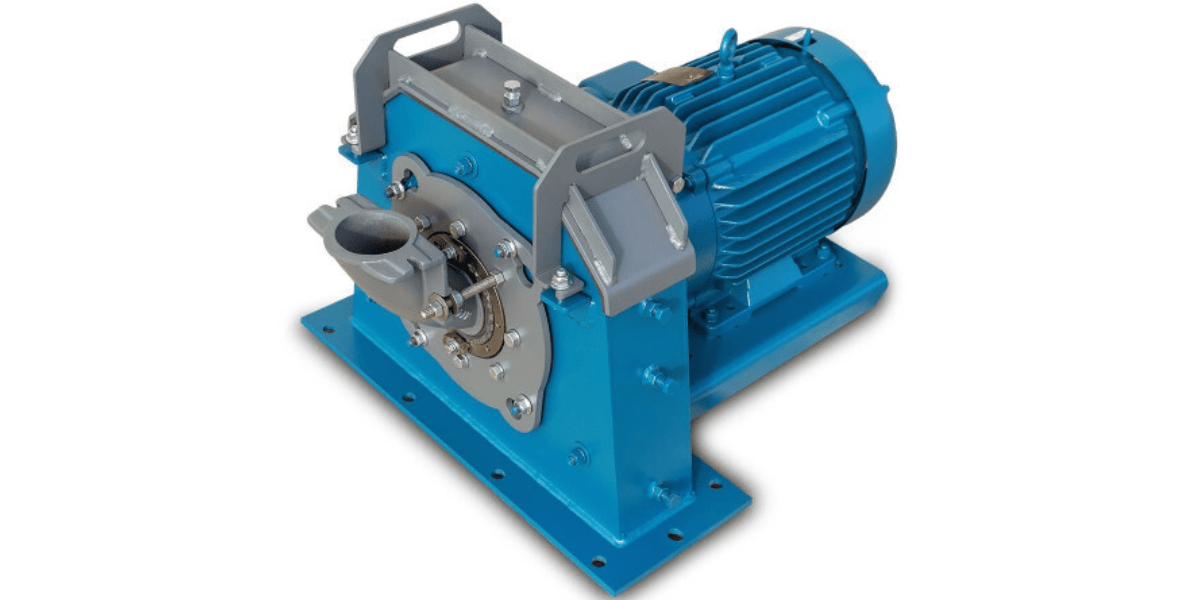

A Blast Wheel is used in shot blasting machines. It is like the heart of the machine because it throws abrasive media onto the surface at high speed for treatment. The process can be used to clean, peen, or prepare the surface for further treatment. In this process, electrical energy is converted into kinetic energy by the sandblasting wheel, which speeds up steel shots, steel grits, or other metallic abrasives. High-speed impacts of these abrasives on surfaces remove contaminants, rust, and scales giving a clean smooth finish.

Contents

Uses of Sandblast Wheel

A wide range of industrial applications have seen the blast wheels used for surface treatment effective and efficient. Some of the main uses of blast wheel in the shot blasting machine are:

- Surface Preparation: This is important because it ensures that surfaces are ready for painting, coating, or plating.

- Cleaning: These remove rust, scale, and other contaminants from metal surfaces.

- Peening: Sandblast wheel increases the mechanical properties of metal components by inducing residual compressive stresses in them.

- Deburring: This makes the edges smooth and removes burrs on machined parts.

- Descaling: The shot blast wheels clean off any scales formed on steel surfaces after a flame spray gun has done various heat treatment processes.

- Shot Blasting: They are employed within foundries to clean castings and remove mold sand.

- Texture Finishing: Sandblast wheel gives surfaces a uniform texture thus enhancing their appearance and adhesion qualities altogether.

Benefits of Using Blast Wheel

A Sand blasting machine using blast wheels has several advantages:

- Efficiency: Surfaces are treated quickly and more comprehensively owing to high-speed blasting.

- Cost-Effectiveness: Manual labor is minimized while employing other cleaning methods hence saving on costs.

- Consistency: The quality of parts treated by this method is enhanced since they obtain uniform finishes over all surfaces.

- Versatility: It can be utilized with an airless shot blasting machine for various purposes from surface preparation to finishing operations; cleaning or roughening before painting.

- Durability: They can withstand frequent usage as well and are resistant to abrasive wearing out.

- Productivity: Accelerates the surface treatment process thereby increasing the general output.

Shot Blast Wheel Manufacturer in India

In India, we are well-known brands that specialize in manufacturing high-quality shot blast wheels. We use our state-of-the-art technology and materials to ensure that our products meet international standards. We offer different types of shot blast wheels for various kinds of shot-blasting machines and applications as a leading shot blast wheel manufacturer in India. What sets them apart is their commitment to quality, innovation, and customer satisfaction in the field of industrial surface treatment. Their expertise in designing and manufacturing leads to durable and efficient blast wheels which enhance the performance levels achieved by shot blasting machines.

Sandblast Wheel Supplier

We make sure that our products meet the highest quality and performance standards because we are a leading sandblast wheel supplier. We manufacture these blast wheels from our state-of-the-art technology and subject them to rigorous durability and efficiency tests. Our stock is vast with different sizes and specifications of blast wheels to suit our customers’ varied needs. We are also well well-known supplier of a diabola shot blasting machine, vacuum shot blasting machine, sand blasting room, thermal spray gun, arc spray gun, wet blasting cabinet, and other blasting equipment. We also offer on-time delivery coupled with great customer service for our clients to get nothing but the best for their surface treatment application needs.

Blast Wheel Price in India

As a leading blast wheel supplier and manufacturer, we provide the most affordable blast wheel price in India. We have a wide range of blast wheels available at affordable rates but still maintain their quality. Our prices are set in such a way that our customers will get the most out of their money. Additionally, we offer tailor-made solutions and also give discounts for bulk purchases to meet different client’s needs. Kindly reach out to us for a comprehensive quotation and more information about our competitive pricing.